Vulcan Launches Affordable MX Series Metal 3D Printers, Starting at $39,000

Mount Laurel, NJ , Oct. 07, 2025 (GLOBE NEWSWIRE) -- Vulcan, a U.S. based manufacturer of advanced manufacturing systems, announced today the launch of its MX Series, a new generation of laser powder bed fusion (LPBF) metal 3D printers that make industrial-grade additive manufacturing accessible to businesses of all sizes. With prices starting at just $39,000, Vulcan offers the most affordable metal 3D printer in the world, without compromising on quality or performance.

Industrial manufacturing is in a period of rapid change. Aerospace, automotive, medical, and energy producers are all looking for ways to make parts that are lighter, more complex, and delivered faster, while also keeping costs under control. Traditional machining remains indispensable, but its dependence on heavy tooling, long lead times, and material-hungry processes makes it tough to keep up with today’s fast-changing demands and the uncertainties of global supply chains.

Metal 3D printing, often called additive manufacturing, is quickly becoming a game-changer for modern production. Instead of carving parts out of large blocks of metal, it builds them up layer by layer, using only the material needed and making complex shapes that traditional methods can't match. For years, though, many businesses saw industrial metal printing as out of reach, either because the technology was too costly or because it simply couldn’t deliver at scale.

A new generation of metal 3D Printers

Vulcan’s new MX Series of metal 3D printers is designed to bridge the gap between cost and capability. The lineup includes eight models, making industrial additive manufacturing accessible to both small labs and large-scale producers. At the entry point is the MX100, a compact system for precision components in tight workspaces, priced at just $39,000. At the other end is the MX800, one of the industry’s largest LPBF systems with a massive 800 x 600 x 900 mm build volume, engineered for manufacturers with heavy production requirements. With six additional models in between, the MX Series offers a clear path to adoption for organizations of any size.

Technology Built for Precision and Flexibility

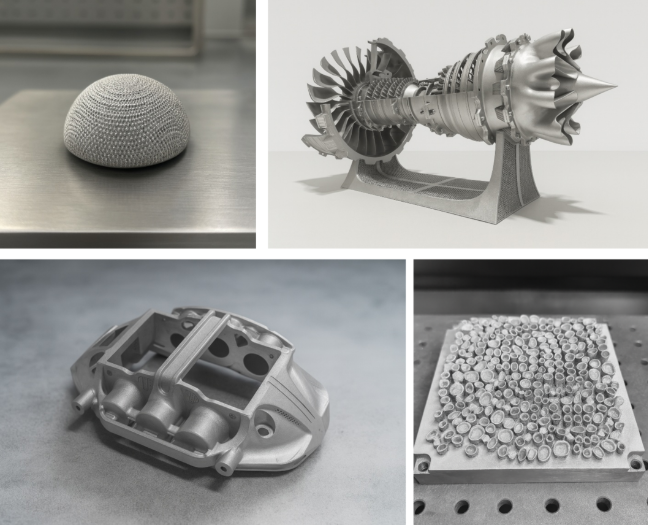

Inside every MX printer, high-power lasers fuse fine metal powders into dense, high-strength parts. Layer thicknesses range from 20 microns for ultra-fine detail to 120 microns for faster builds, enabling both precision and productivity. The result: components with smooth surfaces that often require little to no post-processing, helping manufacturers cut lead times dramatically from design to finished part.

The MX Series also supports a wide range of advanced materials, including titanium alloys for lightweight strength, cobalt-chromium for wear resistance and biocompatibility, copper alloys for superior thermal and electrical conductivity, and an extensive selection of stainless steels and aerospace-grade aluminum alloys. This flexibility makes the MX Series suitable for everything from dental restorations and medical implants to turbine blades, heat exchangers, and structural automotive parts.

Vulcan has focused on making high-end metal printing efficient and straightforward. Multi-laser configurations with intelligent scanning reduce build times while maintaining uniform quality across the entire build area. Closed-loop powder handling and recycling improve operational safety and minimize waste, while automated calibration and intuitive software interfaces shorten training requirements, so teams can move quickly from initial setup to consistent daily production.

Cost Efficiency and Rapid Return on Investment

One of the strongest arguments for adopting metal additive manufacturing is its impact on cost per part and long-term return on investment. By producing components in house, manufacturers avoid many of the hurdles of outsourcing: shipping, long lead times, and high unit pricing, while also avoiding the complexity of subtractive manufacturing like CNC milling. Additive processes use only the material needed, reducing waste and further lowering costs. Across the range, from the compact MX100 to the high-capacity MX800, this efficiency often means a full payback period in just a few months, with lasting reductions in unit costs over the life of the machine.

A New Standard for Accessible Metal 3D Printing

The MX series highlights how far metal 3D printing has progressed from its early experimental days. By combining precise laser-based production with a broad range of materials and pricing that makes industrial adoption practical, Vulcan gives manufacturers a realistic way to integrate additive manufacturing into everyday work.

As production methods continue to evolve toward greater speed, flexibility, and efficiency, these metal 3D printers illustrate how additive technology can become part of standard manufacturing practice. Instead of a specialty reserved for a few applications, metal 3D printing is now positioned to support regular, large-scale production, offering companies new freedom to design and deliver complex parts with confidence.

For more information or to request a demo, visit www.VulcanUSA.com or contact info@VulcanUSA.com.

info@VulcanUSA.com www.VulcanUSA.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.